Even a single normalizing session will help but in the end the grain will not be at its best, each cycle further refines the grain with diminishing returns each time. Three times is a good number of cycles and will get you the most out of your steel.

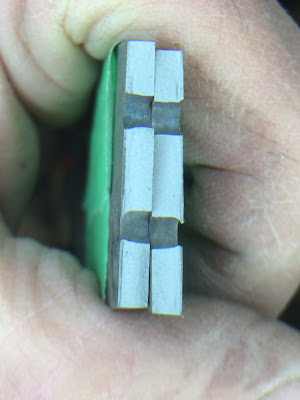

Below is a picture of the different possible levels of grain refinement typically seen in forging.

Factory heat treat will always be better than any normalizing in a forge due to much better control over the temperature and atmosphere of the furnace.

The following two pictures are of blades heat treated in a Evenheat furnace without Normalizing, these were stock removal blades in 1095 and 154 CPM. Both of these materials come from the supplier ready for heat treating.

This is CPM 154

This blade was AISI 1095

You will notice there is a rusty area on the steel in the tapered area of the blade. This knife cracked during a Brine quench when held for a couple seconds too long. Flash rusting was caused by the high temperature of the steel when exposed to water and then air.

This is a perfect example of why 1095 steel under 1/4" thick (nominal thickness) should not be brine quenched. Call it a failed experiment with a $400.00 knife that should never have happened.

Looking at the bottom picture you can see the cracks opened up very nicely. This actually took some time and blade was at room temperature for over an hour before they stopped opening up.

As you can tell there was a lot of stress during quenching that was sufficient to curve the blade which is also the mechanism that causes a Japanese sword to bend during the quenching cycle.

Now according to some very old documents it is supposed to be possible to use water as the first step in a interrupted quench. The provision is it has to be water as that is a slower quenching medium and the quench time can only be around two seconds, and steel must not drop below 900F before going into a hot oil bath (130F) minimum and then let the steels temperature stabilize before removing and allowing to air cool too room temperature.

Tempering must be carried out immediately in this case as the steel is under a great deal of stress and will crack the first chance it gets.

No comments:

Post a Comment